Feed particle size: less than 400mm

Production capacity: 8-900t/h

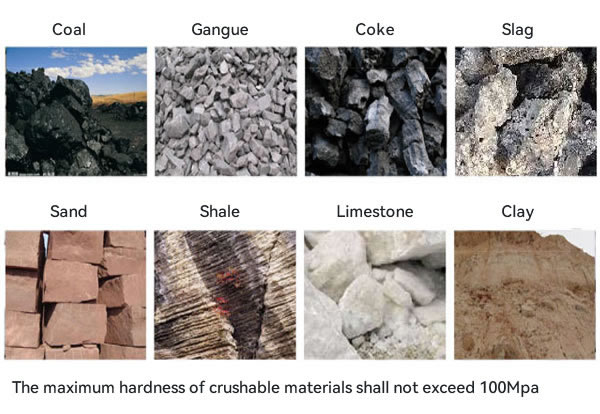

Applicable materials: Various medium hardness materials with a moisture content not exceeding 12%, such as coal, coal gangue, coke, slag, red sandstone, shale, loose limestone, etc.

Dear [Ring hammer crusher] customer, thank you for visiting the Gitega crusher Ring hammer crusher cooperative partner--Maoxin Machinery official enterprise website! Over the years, Maoxin Machinery has insisted on taking research and development as the basis of survival, and constantly improved the application of new technologies in [Ring hammer crusher] products! Inspiring the world through innovation. If you want to know more about the application of [Ring hammer crusher] product new technology in practice, please call Maoxin Machinery [Ring hammer crusher] technical consultation hotline: [+86 18539447368] to learn more new information!

The ring hammer crusher is an ideal coal crushing equipment recommended for improvement based on the difficulty of crushing wet coal in the coal crushing industry. The unique structure of this machine is very suitable for crushing both dry and wet materials, with the advantages of high crushing ratio, no blockage, less hammer wear, and high production efficiency.

The compressive strength of crushed materials does not exceed 150MPa, and the moisture content is 15%, such as coal, coal gangue, coke, slag, limestone, asbestos stone, phosphate ore, pyrite, limonite, etc. The ring hammer crusher is widely used in coal stations and coal transportation stations to crush raw coal.

The main body is composed of the following components: frame part, rotor part, castor plate part, synchronous adjustment device, upper cover hydraulic opening device, and other components. The host is connected to the motor by a hydraulic coupling, and the main working component of the ring hammer crusher that directly starts is the rotor with a ring hammer. The rotor is composed of components such as a ring hammer shaft and a ring hammer.

The ring hammer can not only rotate with the rotor, but also rotate around the hammer shaft. The hammer head that breaks the ring hammer will rotate 360 degrees around the fixed shaft. The motor drives the rotor to rotate at high speed in the crushing chamber. The materials that need to be crushed are transported from the upper feeding port to the machine, and are crushed by the impact of high-speed rotating ring hammers, as well as the collision, compression, and grinding effects between materials. Below the rotor section, there is a castor plate. The particle size of materials that are smaller than the size of the castor plate hole are discharged through the castor plate. Materials that are larger than the size of the castor plate hole continue to be hit by the ring hammer, and then are discharged through the castor plate outside the machine. Materials and debris that cannot be crushed enter the metal collector and are regularly removed.

1. The feeding port is large, with characteristics such as high crushing ratio, high production capacity, and uniform product particle size

2. The hammer head is made of manganese steel material and cast. The service life of the hammer head of a regular hammer crusher is 3-4 times longer than that of a regular forged hammer head

3. It is allowed to add a certain amount of moisture to the material during crushing to reduce dust pollution and protect the health and environment of workers.

4. The sieve plate size is adjustable, the product particle size is controllable, and the particle shape is good.

5. The structure is simple, easy to install, and the chassis can be flipped, making maintenance more convenient.

6. It integrates the functions of impact, counterattack, and impact (stone crushing) into one, with high production efficiency, low wear of machine parts, and significant comprehensive benefits. It is widely used in artificial sand making.

7. Compact structure and strong machine rigidity.

8. The uniquely designed circular hammer head has the functions of high-speed impact and low-speed rolling, making the finished material finer.

| Model | Max feed size (mm) |

Diacharge size (mm) |

Capacity (t/h) |

Rotor Speed (r/min) |

Power (kw) |

Weight (t) |

Dimension (L*W*H)(mm) |

||

| PCH0402 | 200 | ≤30 | 8-12 | 960 | 5.5 | 0.8 | 810*890*560 | ||

| PCH0404 | 200 | 16-25 | 970 | 11 | 1.05 | 980*890*570 | |||

| PCH0604 | 200 | 22-33 | 970 | 15 | 1.43 | 1050*1270*800 | |||

| PCH0606 | 200 | 30-60 | 980 | 30 | 1.77 | 1350*1270*1080 | |||

| PCH0808 | 200 | 70-105 | 740 | 45 | 3.6 | 1750*1620*1080 | |||

| PCH1010 | 300 | 160-200 | 90 | 6.1 | 2100*2000*1340 | ||||

| PCH1016 | 300 | 300-350 | 155 | 9.2 | 2700*2000*1350 | ||||

| PCH1216 | 350 | 620-800 | 355 | 15 | 2965*2500*1600 | ||||

| PCH1616 | 400 | 700-900 | 400 | 19.3 | 5365*2500*1680 | ||||

Why choose Maoxin Machinery for cooperation negotiation? The key word "integrity and win-win" Maoxin Machinery business philosophy can be summed up in eight words "honesty based, win-win development". Maoxin Machinery has always implemented this concept well for both its internal employees and external Ring hammer crusher partners, thus gaining long-term good business reputation and cooperative relations in the broken stones field, and promoting the stable development of Maoxin Machinery.

What makes us different - the collective talent of our people - makes it all possible. Thank you for your attention to the Gitega crusher Ring hammer crusher cooperative partner--Maoxin Machinery website, and welcome your valuable suggestions , If you have any questions about Maoxin Ring hammer crusher, please call Maoxin technical engineer at [+86 18539447368]. Good products in China, serving all human beings!